Installation of double wall corrugated pipe HDPE

(1) The double wall corrugated pipe HDPE shall be constructed and measured according to the pipe coordinates specified in the overall plan before the pipe laying machinery and equipment, and the accurately positioned building reinforcement shall be set. The metal corrugated pipe shall be fixed on the accurately positioned building reinforcement, and the iron wire shall be tied tightly. The spacing between the accurately positioned building reinforcement shall not exceed 0. 8m, the trend map pipeline should be properly encrypted.

(2) The butt joint of double wall corrugated pipe HDPE and anchor seat shall be wrapped with waterproof tape for close connection and sealing. The butt joint wire hole of post tensioning method hole on anchor seat shall also be blocked with waterproof tape to prevent mixed mortar from entering the pipe or wire hole during concrete pouring.

(3) The butt joint of plastic bellows management center can be connected by butt waterproof casing hoop, or thermoelectric arc laser welding and branch pipe arc welding. The set temperature of the pipe welding machine is 250 ℃. Power 800W, temperature rise time 30-658.

(4) When the length of the prestressed tendon is more than 50m, the plastic pipe hoop with investigation hole shall be reasonably arranged at each additional 50rn position as far as possible, and the installation direction shall be selected at the high and low points of the prestressed tendon as far as possible.

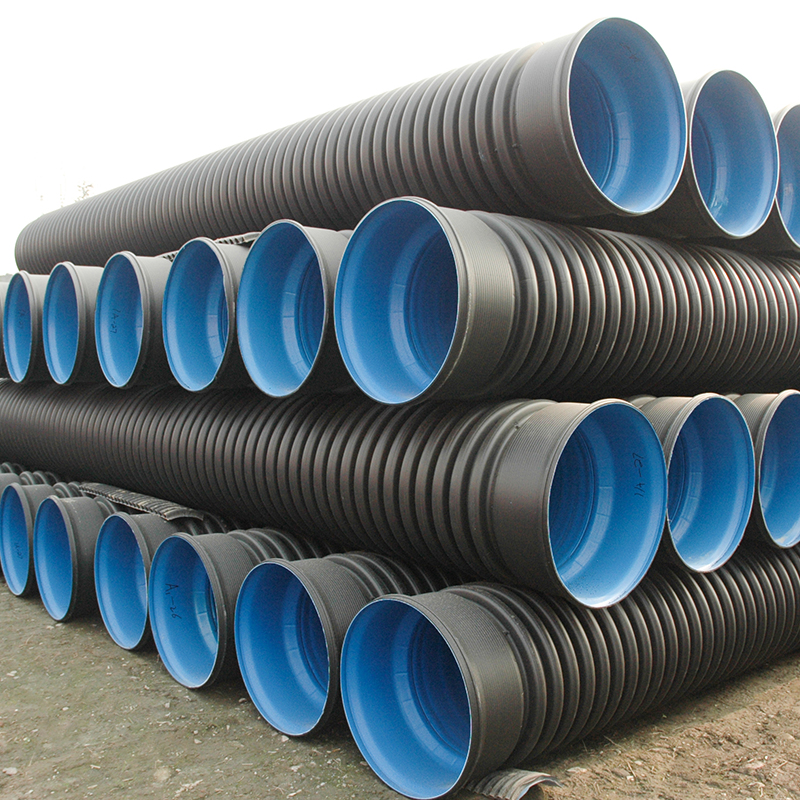

Prestressed plastic corrugated pipe circular steel pipe is mainly used in post tensioned prestressed concrete structure and pile forming of prefabricated components. The ZY plastic produced by the company is made of high-density polyethylene (HDPE Double wall) with high relative density and excellent production process. It has the advantages of good sealing, no slurry leakage, high ring stiffness, small friction resistance, aging resistance, electric corrosion resistance, good flexibility, not easy to be chiseled by tamping rod, and new docking methods, which make the docking of construction more convenient and fast.

Plastic bellows is a component connecting pipes. In addition, it is also an important component of machinery and equipment pipes. When the machinery and equipment are in operation, the machinery and equipment pipeline will be offset, industrial equipment deformation and vibration due to external factors. Because the pipeline itself has no ductility, once the industrial equipment deformation or offset occurs, the pipeline will be damaged. But I don't know that plastic bellows can compensate for such pressure as deviation, deformation and vibration of industrial equipment for machinery and equipment pipelines, so as to effectively ensure the healthy operation of industrial equipment pipelines.

Scope of commodity application of double wall corrugated pipe HDPE: prestressed plastic corrugated pipe is mainly used in road, highway, bridge, tunnel construction, engineering project construction, water conservancy and hydropower project, power installation project and other important construction projects in China.

Product characteristics of prestressed plastic bellows: 1. Bending stiffness test: radial deformation ≤ 0.1d2 under concentrated load of 0.75kn or uniform load of 1.5kn. Impermeability grade test: water injection or mixed mortar with concrete water cement ratio of 0.5 has no leakage and slurry running for 30 minutes. 3. Tensile strength test: axial tensile strength 5kn and wall thickness has no damage. 4 Pull out test: the pull-out force of the pavement in the concrete is more than 2.3 times of the design pull-out force of the anchor bolt scheme. 5. Tensile strength test: when the bending number is 30 days of the intersection angle, there is no leakage and slurry running.