Product introduction:

MPP (modified polypropylene) power cable protection pipe is a construction process of laying pipes and cables in special sections such as roads, railways, buildings and riverbed without dredging, soil excavation and pavement damage. Compared with the traditional "trenching and burying pipe method", the trenchless power pipe project is more suitable for the current environmental protection requirements and removes the disturbing factors such as dust and traffic congestion caused by the traditional construction. This technology can also lay pipelines in some areas where the excavation operation cannot be carried out, such as historic sites protection areas, downtown areas, crop and farmland protection areas, highways, rivers, etc.

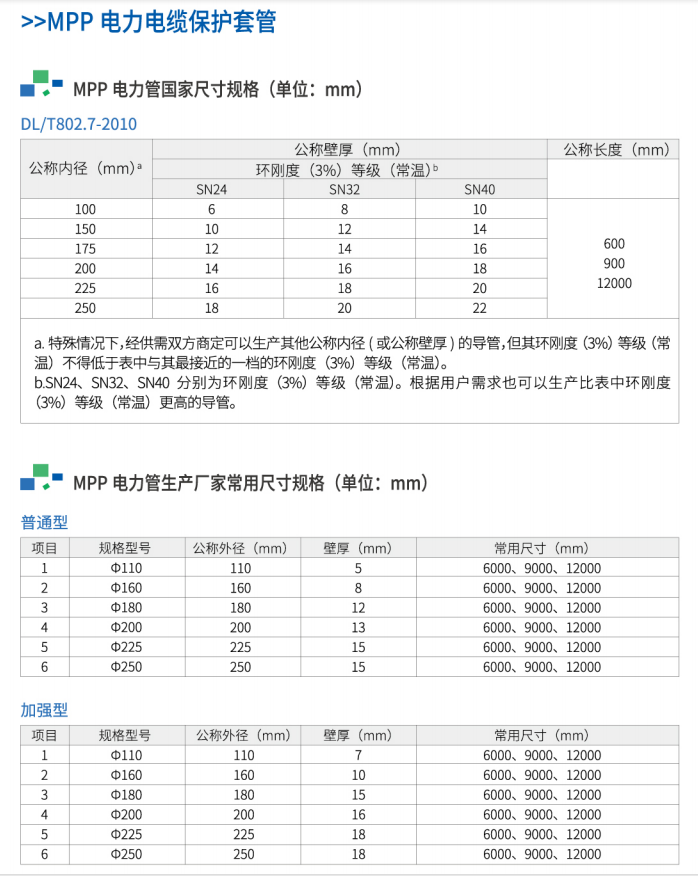

MPP (modified polypropylene) power cable protection pipe has the characteristics of high temperature resistance and external pressure resistance. It is suitable for the pipe of cable Bank of high-voltage transmission line above 10kV. The common specifications of pipes are Φ 110 ~ Φ 315, divided into ordinary type and reinforced type. The common type is suitable for excavation laying construction and trenchless crossing construction, and the buried depth is less than 4m; The reinforced type is applicable to projects with a buried depth of more than 4m in trenchless crossing construction.

Instructions for HDPE construction of double wall corrugated pipe:

1. During the transportation and construction of pipes, it is strictly prohibited to throw, impact, scratch and expose to the sun.

2. During hot-melt butt joint, the axes of the two pipes shall be aligned, and the end face cutting shall be vertical and flat.

3. The processing temperature, time, pressure and shall be adjusted accordingly according to the climatic conditions.

4. The minimum bending radius of the pipe shall be ≥ 75 pipe outer diameter.